Weaving Consultancy

Expert guidance in technical weaving and narrow composite reinforcements

Eurocarbon provides specialised weaving consultancy for customers developing composite components using technical woven tapes and narrow fabrics. With decades of experience in weaving carbon, glass, aramid and hybrid materials, we help customers select woven reinforcements that are technically appropriate, manufacturable and cost-effective.

Our consultancy focuses on textile architecture, material selection and production feasibility. We do not provide mechanical strength calculations or downstream handling and placement consultancy.

What We Offer

1. Technical Weaving Consultancy

Narrow woven tapes & structural fabrics

We support customers in selecting and configuring woven reinforcements by advising on:

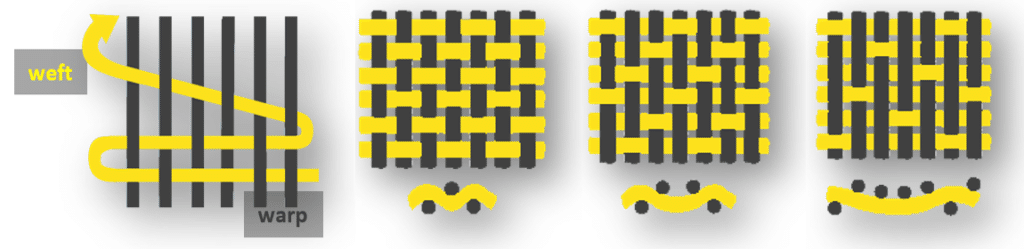

- Tape width, thickness and weave pattern (max witdth is 360mm wide)

- Fibre type selection (carbon, glass, aramid, hybrids)

- Fabric architecture and yarn distribution

- Edge behaviour and dimensional stability

- Surface quality and consistency

- Production feasibility and cost implications

2. Standard Programme as Starting Point

Fast and reliable entry into production

For most applications, customers can start with Eurocarbon’s standard woven tape programme, which offers:

- Proven constructions

- Stable quality and repeatability

- Competitive cost levels

- Short lead times

This allows customers to begin development quickly, without unnecessary complexity.

3. Custom Tape Development & Fine-Tuning

Optimising where it adds real value

Once a baseline is established, we support targeted customisation, such as:

- Adjusting tape width or construction

- Modifying weave pattern within production limits

- Hybrid material combinations

- Custom tape designs for specific geometries or interfaces

This step-by-step approach ensures technical optimisation without cost escalation.

4. Material Selection & Application Fit

Choosing the right reinforcement concept

We advise when woven tapes are the most suitable solution, and how they compare to alternative reinforcements:

- Woven tapes vs braids

- Hybrid solutions combining woven tapes with overbraiding

- Hybric solutions combining woven tapes with refular braids to simulate a triaxial structure for bending and torsion loads.

- Tubular Elastic UD Woven Tape

- Tublar braid

Our guidance is based on manufacturing practicality and application requirements, not theoretical optimisation.

5. Prototype Support & Small-Series Production

Validation before scale-up

Eurocarbon supports customers with:

- Sample tapes from the standard programme

- Custom development samples

- Small-series production for trials

- Transition from development to series production

This allows customers to validate their reinforcement choice before committing to larger volumes.

Industries We Support

- Defence – launcher tubes, UAV structures, protective sleeves

- Aerospace – lightweight reinforcements, insulation tapes, gusset fillers

- Automotive – driveshafts, energy absorption components

- Industrial – robotics, machinery reinforcement, protective materials

- Sporting goods – ski, rackets, hockeysticks

- Healthcare – Prostetics, lightweigt reinforcements

- Marine – Canoes, lightweigt reinforcements

- Insulation – Thermal and electrical insulation

Why Eurocarbon?

- Over 40 years of experience in technical weaving

- In-house production of narrow woven tapes from up to 360 mm wide

- Clear focus on production feasibility and cost control

- Step-by-step development: standard → custom where needed

- Integrated offering: consultancy → development → production

- European manufacturing with full material traceability

Discuss Your Weaving Application

Contact Eurocarbon to discuss your application or to start with our standard woven tape programme.

Let’s Develop Your Fibre Architecture Together

Contact us to schedule a consultancy session or discuss your application.

Please see the following for more information about Eurocarbon and its capabilities:

Standard Programs

To achieve a higher level of customer service, we have successfully implemented our standard product programmes for many years.

Thermoplastics

Besides our selection of standard programs, Eurocarbon produces a large variety of tailor made constructions.

Overbraiding & equipment

Overbraiding is the technique used to produce net shape cost-effective structural preforms.

Custom made

We provide custom / tailor made solutions for our customers. Check the basic information required for a product proposal.

Would you like to get more information? Get in contact with one of our Agents!

Your project in 4 steps

1

The problem

2

Quotation

3

Production

Delivery

Have we convinced you yet?

Fill in the form without obligation!

Our sales team will invetigate your request and propose the best solution for your application.

Even when a bit information is shared we know how to proceed further. Ofcourse if a NDA is required, we can settle this together.