What is Triaxial Braiding?

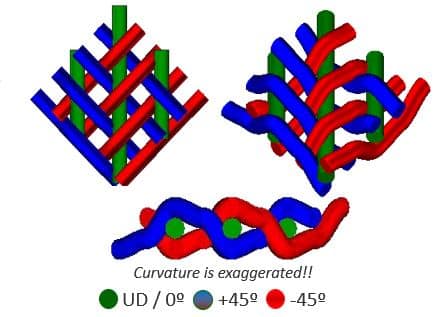

Triaxial braiding is an advanced technique in which three yarn systems are interlaced—typically oriented at ±45° and 0°—to form a multidirectional reinforcement. Unlike biaxial braids, which include only ±45° fibers, triaxial braiding adds longitudinal 0° fibers—significantly increasing axial stiffness and structural balance. This creates a highly stable, multidirectional reinforcement structure. The 0° unidirectional fibers enhance axial stiffness, while the ±45° bias fibers provide torsional and shear strength—making triaxial braid ideal for dynamic, load-bearing parts.

Standard and custom-made

In-house production

ISO 9001 certified quality management

What our customers say about us

How We Offer Triaxial Solutions

As a specialist in braiding consultancy, we understand that off-the-shelf materials often fall short in meeting complex engineering requirements. That is why we offer tailor-made triaxial braids, developed using our own braiding equipment and automation systems. Whether you need a full preform, a hybrid solution, or integration with other reinforcements, we work alongside your engineering team to deliver the right result—efficiently and reliably. We can produce triaxial braids using a wide range of high-performance materials, including carbon fiber, glass fiber, aramid and thermoplastic yarns.

A triaxial braid is a type of textile architecture commonly used in composite materials, especially in high-performance applications like aerospace, automotive, and sporting goods.

What is a Triaxial Braid?

A triaxial braid consists of three sets of yarns:

-

Two bias yarns: These are braided at opposing angles (f.i. 45° or 60°) to the axis.

-

One axial yarn: This runs straight along the axis of the braid (0° orientation).

This differs from a biaxial braid, which has only the two bias yarns and no axial fibers.

Visually, the bias looks like a criss-cross pattern of yarns wrapped around a mandrel, with an inner layer of straight UD fibers running lengthwise.

Check also our Cobracomp architecture with 2 interlaced braiding layers and 3 levels of UD fiber.

Benefits of Our Triaxial Braids

- Improved Strength and Stiffness Along the Axis (0°)

The axial yarns significantly enhance tensile and flexural strength (so bending and torsion integrated into one layer) in the longitudinal direction, where loads are often highest. - Quasi-Isotropic Behavior

The combination of ±bias and 0° axial fibers gives a more uniform distribution of mechanical properties in all directions (quasi-isotropic Bias 60° + 0°), especially in-plane.

This makes it particularly suitable for tubes, rods, and structural members that experience multidirectional loads. - Damage Tolerance & Delamination Resistance

The interlaced structure improves impact resistance and reduces the likelihood of delamination compared to unidirectional or layered composites. Our overbraided Mercedes Mclaren SLR crashcone is a perfect example for this property. - Good Conformability

Triaxial braids can be formed over complex shapes without wrinkling or bridging, which is advantageous in resin transfer molding (RTM) and similar processes. - Manufacturing Efficiency

Braiding is a continuous, automated process, allowing for high repeatability and consistent fiber placement—ideal for scalable production.

Our triaxial braiding allows to produce near-net-shape reinforcements with improved structural integrity—whether straight or complex in form.

Triaxial and overbraiding

Overbraiding is the perfect technology to make triaxial architectures. This is the only method for shapes with a variable diameter/geometry.

Once braided, the diameter of the braided architecture can’t expand/increase to a large diameter anymore as the 0° will be compressed in this scenario.

Alternatives if Overbraiding isn’t an option? Use our Carbon Braids or Glass Braids in combunation with Tubular Elastic UD.

Triaxial and continuous braiding

Triaxial braids can be ordered as a continuous sleeve or cut open on one side to form a fabric with a specific width.

Get in touch with our braiding experts

Partner with Us for Tailor-Made Reinforcements

At Eurocarbon, we do not just deliver material—we deliver expertise. We support your project from the initial concept through to production. Whether you need standard solutions or fully customized braids, our team is ready to assist you with the right configuration, material selection and design optimization. Get in touch with us today to explore how triaxial braiding can elevate your composite application.