Preforms made by the Overbraiding Technique

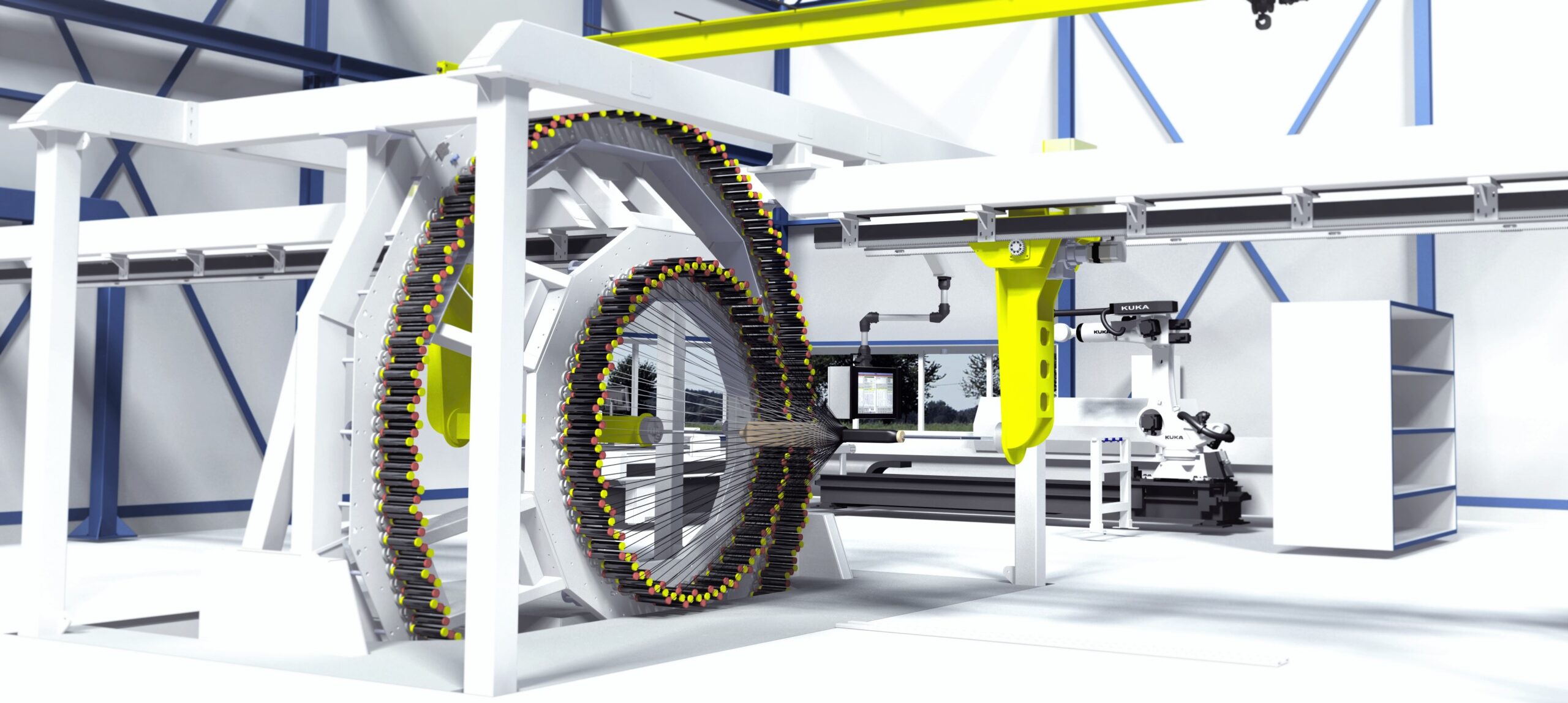

• Overbraiding is the technique used to produce net shape cost-effective structural preforms.

• During overbraiding the braid is placed directly onto a core, which has the inner geometry of the desired preform.

• By reciprocating the core through the braiding point a pre-selected number of layers can be braided to obtain the desired wall thickness/aerial weight.

• The lightweight core can remain in the product or a lost core technique can be used for production of a hollow product.

Benefits of Overbraiding

• Cost effective method and low waste rates (5-10%).

• Reproducible due to computer control and automated processes.

• Time saving compared to building your own preforms manually.

• Braiding angles are programmable from 15° to 80°.

• 0° (UD) yarns can be integrated to form a tri-axial braid.

• The ratio between bias and UD can vary from 100/0 up to 15/85.

• Hybrids are possible in the bias and in the UD direction.

• Excellent energy absorption in crash structures. Braided structures act as crack stoppers.

• Braided structures have a good resin permeability.

• Eccentric products are possible, even banana shaped preforms.

• Preforms injected with the RTM process can have a fiber volume fraction of 55%.

What we offer

• For each product an overbraiding machine and yarn configuration can be selected to produce your optimum preform.

• We have 15 years of experience in overbraiding and we are able, with our R&D team, to do the total preform development at Eurocarbon/Eurobraider.

• When a special braiding machine or extra equipment is needed, we can build it.

• We can offer a turn key solution and transfer of know-how, so you can produce your own preforms.

• Preform development and preform production can be done entirely in house..

Would you like to get more information? Get in contact with one of our Agents!

Your project in 4 steps

1

The problem

2

Quotation

3

Production

Delivery

Have we convinced you yet?

Fill in the form without obligation!

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Praesent vitae augue eu quam varius pulvinar in sit amet nunc. Proin quis dignissim neque, vitae gravida tellus. Quisque sollicitudin tristique lacus a placerat. Vestibulum consectetur quam sit amet nisi consequat, vel scelerisque.