Services

Advanced fibre solutions, consultancy and production capabilities

Eurocarbon provides a complete range of services supporting customers who require high-quality fibre reinforcements, composite preforms and specialised braiding or weaving expertise. Our service offering spans consultancy, development support, industrial production and custom machine engineering.

Our Core Services

1. Braiding & Weaving Consultancy

Fibre architecture, process guidance and manufacturability

We help customers choose the right fibre architecture and production method for their design. With over 40 years of experience in braids, woven tapes, UD reinforcements and hybrid constructions, we advise on:

- Biaxial & triaxial braid configuration

- Weaving patterns for technical tapes

- Material selection (carbon, glass, aramid, thermoplastic fibres)

- Feasibility of shapes and preforms

- Practical production considerations (angles, tensions, coverage)

Our consultancy focuses on process and architecture, not on strength calculations.

→ Read more about Braiding & Weaving Consultancy

2. Overbraiding Consultancy

Seamless 360° reinforcement for tubes, transitions and complex geometries

Eurocarbon is one of Europe’s most experienced overbraiding specialists. We support customers in designing and optimising overbraided preforms by advising on:

- Overbraiding feasibility

- Cones, transitions and multi-diameter shapes

- Mandrel integration (metal, polymer, foam)

- Angle strategy and machine configuration

- UD or tape reinforcement integration

→ Read more about Overbraiding Consultancy

3. Composite Production & Manufacturing

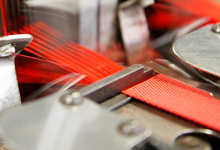

Industrial-scale braiding, weaving and preform production

We manufacture high-quality reinforcement materials:

Braids & Sleeves

- Biaxial & triaxial braids

- Carbon, glass, aramid and hybrids

- Thermoplastic or hotmelt options

Woven Tapes

- Narrow fabrics in various widths

- Edge-stable constructions

- Binder/hotmelt integration

UD & Hybrid Materials

- Elastic UD

- UD-braid combinations

Overbraided Preforms

- Tubes, cones, transitions

- Prototypes to full series production

→ Read more about Composite Production

4. Machine Development

Custom braiding machines and equipment engineering

Eurocarbon is also developing specialised braiding equipment for industrial, aerospace and R&D environments. We provide:

- Custom-designed braiding machines

- Overbraiding systems

- High-speed production braiders

- Upgrades, modifications and support

→ Read more about Machine Development

5. Development Support & Prototyping

From idea to production-ready fibre reinforcement

We help customers validate and industrialise concepts by offering:

- Prototype braids and preforms

- Material trials

- Sample tapes and UD variants

- Early-stage feasibility and guidance

Why Work With Eurocarbon?

- Over 40 years experience in braiding & weaving

- One of Europe’s most capable overbraiding facilities

- Integrated offering: consultancy → development → production → machinery

- Proven across defence, aerospace, automotive and industrial applications

- Focus on manufacturability and real-world production constraints

Please see the following for more information about Eurocarbon and its capabilities:

Standard Programs

To achieve a higher level of customer service, we have successfully implemented our standard product programmes for many years.

Thermoplastics

Besides our selection of standard programs, Eurocarbon produces a large variety of tailor made constructions.

Overbraiding & equipment

Overbraiding is the technique used to produce net shape cost-effective structural preforms.

Custom made

We provide custom / tailor made solutions for our customers. Check the basic information required for a product proposal.

Would you like to get more information? Get in contact with one of our Agents!

Your project in 4 steps

1

The problem

2

Quotation

3

Production

Delivery

Have we convinced you yet?

Fill in the form without obligation!

Our sales team will invetigate your request and propose the best solution for your application.

Even when a bit information is shared we know how to proceed further. Ofcourse if a NDA is required, we can settle this together.