Production & Manufacturing

Industrial production of advanced fibre reinforcements and braided preforms

Eurocarbon provides industrial-scale production and manufacturing of high-performance fibre reinforcements and composite preforms. We combine decades of textile expertise with dedicated production equipment to deliver consistent quality, repeatability and reliable supply — from small series to high-volume production.

Our manufacturing capabilities cover braiding, weaving, UD reinforcements and overbraiding, supporting customers across defence, aerospace, automotive and industrial markets.

Our Manufacturing Capabilities

1. Braiding Production

Biaxial and triaxial braided reinforcements

Eurocarbon produces a wide range of braided structures using carbon, glass, aramid and hybrid fibres.

Capabilities include:

- Biaxial and triaxial braids

- Round, oval and special-shaped sleeves

- Controlled braid angles and fibre coverage

- Small diameters up to large structural braids

- Stable, RTM- and infusion-ready constructions

Braided products are supplied as consistent, production-ready reinforcements suitable for structural and functional composite applications.

2. Overbraided Preform Manufacturing

Seamless 360° reinforced composite preforms

Eurocarbon is one of Europe’s leading producers of overbraided preforms, operating custom-designed overbraiders developed in-house.

We manufacture:

- Tubes, cones and transition shapes

- Overbraided structures on metal, polymer or foam mandrels

- Hybrid constructions with local UD or woven tape integration

- Preforms optimised for RTM, VARTM or infusion processes

Our focus is on repeatable geometry, fibre stability and manufacturability in series production.

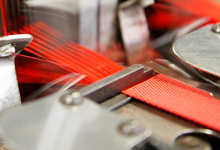

3. Weaving Production

Technical woven tapes and narrow fabrics

Eurocarbon produces technical woven tapes for composite applications, using carbon, glass, aramid and hybrid yarns.

Production includes:

- Narrow woven tapes in various widths

- Stable edge constructions

- Consistent fabric architecture

- Standard tape programme with proven designs

- Custom woven tapes within defined production limits

Customers typically start with standard constructions and refine towards custom solutions where required.

4. UD & Hybrid Reinforcements

Targeted stiffness and local reinforcement

Eurocarbon manufactures elastic UD reinforcements and hybrid solutions combining UD with braids or woven tapes.

These materials are used to:

- Add local 0° reinforcement

- Increase stiffness where required

- Integrate seamlessly into braided or woven architectures

UD and hybrid products are supplied as production-compatible reinforcements, not laboratory materials.

5. Series Production & Quality Control

From repeatable prototypes to industrial volumes

Eurocarbon supports:

- Small-series production for qualification and testing

- Medium- and large-scale series manufacturing

- Consistent quality and dimensional stability

- Controlled material sourcing and traceability

- Reliable long-term supply for OEM programmes

Our production processes are designed for industrial robustness, not one-off demonstrators.

Industries We Supply

- Defence – launcher tubes, UAV structures, weapon components, protective reinforcements

- Aerospace – structural reinforcements, insulation layers, lightweight components

- Automotive – driveshafts, energy absorption structures, lightweight reinforcements

- Industrial – robotics, machinery, pressure and protection applications

Why Eurocarbon Manufacturing?

- Over 40 years of experience in fibre reinforcement production

- One of Europe’s most capable braiding and overbraiding facilities

- Integrated production of braids, woven tapes and UD materials

- In-house machine development and process knowledge

- Focus on repeatability, manufacturability and cost control

- European manufacturing with full material traceability

From Development to Series Production

Eurocarbon supports customers from initial development through to full industrial production, ensuring a smooth transition and reliable long-term supply.

Contact us to discuss your production requirements.

Please see the following for more information about Eurocarbon and its capabilities:

Standard Programs

To achieve a higher level of customer service, we have successfully implemented our standard product programmes for many years.

Thermoplastics

Besides our selection of standard programs, Eurocarbon produces a large variety of tailor made constructions.

Overbraiding & equipment

Overbraiding is the technique used to produce net shape cost-effective structural preforms.

Custom made

We provide custom / tailor made solutions for our customers. Check the basic information required for a product proposal.

Would you like to get more information? Get in contact with one of our Agents!

Your project in 4 steps

1

The problem

2

Quotation

3

Production

Delivery

Have we convinced you yet?

Fill in the form without obligation!

Our sales team will invetigate your request and propose the best solution for your application.

Even when a bit information is shared we know how to proceed further. Ofcourse if a NDA is required, we can settle this together.