Expert guidance in designing and producing 360° tubular braided composite preforms

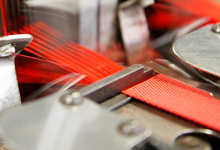

Overbraiding is one of the most advanced methods for producing seamless fibre reinforcements for tubes, transitions, curved shapes and complex mandrels. Eurocarbon is one of Europe’s most experienced overbraiding specialists, operating custom-built overbraiders designed in-house.

Our consultancy service helps customers determine whether their geometry, material and process are suitable for overbraiding — and how to achieve the most stable, repeatable and cost-efficient preform for composite production.

We offer practical, production-driven support, not theoretical strength calculations.

What We Offer

1. Overbraid Feasibility Assessment

Can your part be overbraided successfully?

Before customers invest in tooling or development, we analyse:

- Geometry: tubes, cones, transitions, diameter changes

- Mandrel materials: metal, thermoplastic, foam, soluble or sacrificial cores

- Curvature, draft angles and accessibility for carrier movements

- Minimum / maximum braid angles achievable

- Local distortion risks and fibre displacement

- Stability of the preform during handling and transportation

This reduces risk, avoids unnecessary development costs, and improves the overall success rate of preform production.

2. Fibre Architecture & Process Guidance

Defining the right orientation, angle and reinforcement strategy

We advise on:

- Choosing biaxial or triaxial overbraid structures

- Fibre material: carbon, glass, aramid, hybrids or thermoplastic yarns

- Angle control for optimal 360° coverage

- Combining UD, tape or (NCF)fabric patches during overbraiding

- Managing transitions and local reinforcement zones

- Material handling requirements

- Calculations for thickness, cover factors, layer seqenence

- Check if your part geometry is braidable

Our aim is to create a robust, manufacturable fibre layout suitable for RTM, infusion or thermoplastic consolidation.

3. Machine & Parameter Support

From carrier setup to tension control

We provide expertise on:

- Carrier count needed for your product and configuration

- Tension settings for different fibres

- Mandrel rotation and translation behaviour

- Angle programming and automated control

- Cycle time optimisation

- Preventing gaps, wrinkles or fibre misalignment

This advice is based on decades of in-house production (since 1994) using advanced Eurocarbon-designed machines.

4. Prototype & Preform Development

Turning ideas into production-ready braided shapes

Eurocarbon assists with:

- Single-piece prototype overbraids

- Small-batch development series

- Complex demonstrators for R&D or defence programmes

- Hybrid overbraid structures incorporating UD or woven tapes

- Validation of repeatability and handling behaviour

- Ofcourse we would like to help with large series production

We help teams evaluate their concept before committing to large-scale production.

5. Production Transfer & Collaboration

Smooth transition from development to series manufacturing

For customers aiming to scale up:

- We can produce the preforms in-house

- Or provide consultancy for transferring the process to your facility

- Or support joint development with OEMs, defence agencies and research institutes

6. What we need from you

To start a feasibility study, we typically require:

- Basic geometry (STEP/IGES or drawing)

- Target braid angle or concept

- Expected interface or mandrel material

- Required production volume

- Or support joint development with OEMs, defence agencies and research institutes

Industries We Support

- Defence – launcher tubes, UAV structures, protective sleeves

- Aerospace – lightweight reinforcements, insulation tapes, gusset fillers

- Automotive – driveshafts, energy absorption components

- Industrial – robotics, machinery reinforcement, protective materials

- Sporting goods – ski, rackets, hockeysticks

- Healthcare – Prostetics, lightweigt reinforcements

- Marine – Canoes, lightweigt reinforcements

- Insulation – Thermal and electrical insulation

Why Eurocarbon?

- Among the most experienced overbraiding specialists in Europe

- Custom-built machines with unique capabilities (up to high carrier counts)

- Expertise in complex geometries few companies can produce

- Practical, realistic consultancy based on years of production

- Integrated service: consultancy → prototype → production

- Proven track record in defence, automotive, industrial machinery and R&D

Discuss Your Overbraiding Challenge

Contact us to schedule a consultancy session or request a feasibility review.

Please see the following for more information about Eurocarbon and its capabilities:

Standard Programs

To achieve a higher level of customer service, we have successfully implemented our standard product programmes for many years.

Thermoplastics

Besides our selection of standard programs, Eurocarbon produces a large variety of tailor made constructions.

Overbraiding & equipment

Overbraiding is the technique used to produce net shape cost-effective structural preforms.

Custom made

We provide custom / tailor made solutions for our customers. Check the basic information required for a product proposal.

Would you like to get more information? Get in contact with one of our Agents!

Your project in 4 steps

1

The problem

2

Quotation

3

Production

Delivery

Have we convinced you yet?

Fill in the form without obligation!

Our sales team will invetigate your request and propose the best solution for your application.

Even when a bit information is shared we know how to proceed further. Ofcourse if a NDA is required, we can settle this together.