Woven Fabrics in Composites: Understanding Weave Bindings, Strength, and Drapeability

Including the Key Advantages of Narrow Woven Tapes Over Slit Wide Woven Fabrics

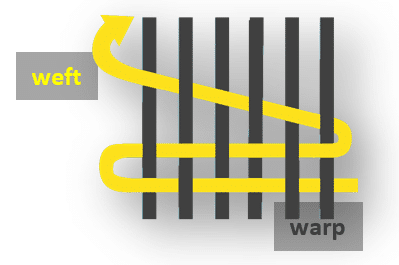

Selecting the right reinforcement is crucial when designing high-performance composite components. The weave binding of a fabric—how the warp and weft yarns interlace—directly affects the strength, drapeability, stability, and processability of a laminate. Each binding type performs differently and is typically used in specific markets such as aerospace, automotive, marine, industrial composites, and sporting goods.

This article explains the differences between the most common weave structures and highlights the advantages of Eurocarbon’s narrow woven tapes compared to slit broadwoven fabrics.

What Are Woven Fabrics in Composites?

Woven fabrics are reinforcement materials made by interlacing fibers such as carbon fiber, glass fiber, aramid, or hybrid combinations. Their structural performance is defined by:

-

Weave type (binding)

-

Fiber type

-

Areal weight (gsm)

-

Fabric width

-

Degree of crimp (Waviness, the more waviness, the less straight fibers, lower performance)

The choice of weave binding is especially important because it influences both mechanical behavior and how easily the fabric conforms to complex geometries.

Overview of Common Weave Bindings

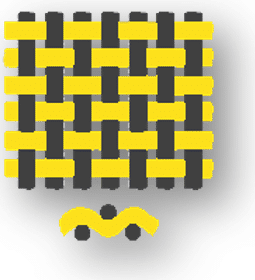

1 Plain Weave (Balanced Weave)

Key characteristics

-

Tight, balanced construction

-

High dimensional stability

-

Many crossover points → higher crimp

Strength

-

Good bidirectional strength

-

Slightly reduced modulus due to fiber bending

Drapeability

-

Moderate

-

Less suitable for deep-drawn or highly contoured parts

Frequently used in

-

Industrial composite parts

-

Flat laminates and tooling

-

Automotive structural reinforcements

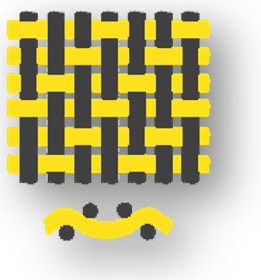

2 Twill Weave (2×2, 3×1, 4×4 Twill)

Key characteristics

-

Diagonal pattern

-

Fewer crossovers → smoother and more flexible

-

Popular aesthetic in carbon fiber components

Strength

-

Improved mechanical performance over plain weave

-

Better impact and fatigue resistance

Drapeability

-

Good to very good

-

Suitable for moderately complex surfaces

Frequently used in

-

High-performance automotive & motorsport

-

Marine composite panels

-

Visible carbon parts (bodywork, design components)

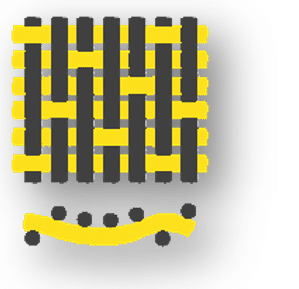

3 Satin Weave (5HS, 8HS, 12HS)

Key characteristics

-

Long floats create smooth, low-crimp surfaces

-

Lowest shear resistance → excellent conformability

Strength

-

Very high tensile strength along fiber direction

-

Superior structural performance

Drapeability

-

Excellent; ideal for deep-drawn or complex shapes

Frequently used in

-

Aerospace structural laminates (stringers, frames)

-

High-end marine applications

-

Advanced industrial composites and RTM/infusion processes

Comparing Strength, Stability, and Drapeability

| Weave | Strength | Drapeability | Stability |

|---|---|---|---|

| Plain | Good | Moderate | High |

| Twill | Very Good | Good | Medium |

| Satin | Excellent | Excellent | Low |

Market-Specific Preferences

Aerospace Composites

-

Prefers satin weaves (5HS/8HS) for high strength and excellent conformity.

-

Common in prepregs, RTM, and infusion.

Automotive & Motorsport

-

Twill carbon dominates visible parts.

-

Structural parts combine twill, UD tapes, and multiaxials.

Marine & Boatbuilding

-

Mix of twill and satin

-

Often combined with stitched multiaxial reinforcements.

Industrial Composites

-

Plain weave where stability is required

-

Twill for parts requiring better drape.

Sporting Goods

-

Twill for design products

-

Satin for structural, high-performance components

Narrow Woven Tapes vs. Slit Broadcloth

Eurocarbon is internationally known for producing precision narrow woven tapes (narrow fabrics) used across aerospace, automotive, and advanced industry.

1 Narrow Woven Tapes

Narrow fabrics are woven directly to the final width (e.g., 10 mm, 20 mm, 30 mm, 50 mm, 100 mm).

This results in:

-

Strong, clean selvedge edges

-

Perfect width tolerance

-

No fraying

2 Slit Broadwoven Fabrics

Broadcloth is woven in widths like 1000 mm and mechanically slit into strips.

This introduces:

-

Edge fraying

-

Loose fibers

-

Width variation

-

Additional trimming steps

Advantages of Narrow Woven Fabrics

✔ No fraying — woven selvedge edges

-

Clean, strong edges

-

Eliminates trimming and edge reinforcement

✔ Superior dimensional stability

-

Guaranteed width tolerance

-

Fibers stay aligned and tensioned

✔ Cleaner production

-

No fiber dust or cutting debris

-

Ideal for aerospace & prepreg production

✔ Higher process efficiency

-

No post-processing

-

Lower waste and shorter cycle time

✔ Ideal for automated layup

Automation requires consistent, repeatable material.

Narrow tapes offer:

-

Consistent width

-

Stable tension

-

Reproducible fiber alignment

These benefits cannot be matched by slit material.

Where Narrow Fabrics Are Used

-

Aerospace spar caps & stringers

-

Automotive localized reinforcements

-

Industrial tubes and pressure vessels

-

High-performance sporting equipment

-

Medical and technical textile applications

Conclusion

Choosing the right weave binding is essential for achieving optimal performance in composite structures.

Plain weave offers stability, twill provides an attractive balance of drape and strength, and satin delivers exceptional performance for demanding, high-complexity shapes.

Narrow woven tapes offer significant advantages over slit broadcloth—from clean selvedges to perfect dimensional accuracy—making them the preferred choice in aerospace, automotive, industrial, and other high-end composite applications.

With decades of expertise, Eurocarbon supplies advanced woven reinforcements and narrow fabrics tailored to the requirements of modern composite manufacturing.

Interested?

Need something else?

Would you like to get more information? Get in contact with one of our Agents!

Your project in 4 steps

1

The problem

2

Quotation

3

Production

Delivery

Have we convinced you yet?

Fill in the form without obligation!

Overbraiding will provide a cheap solution for your product to handle torsion and bending loads at a low waste rate.

Send us your sketch and we can go from there!