How it started

During one of our overbraiding presentations at a conference interest was triggered for Scheldebouw to handle the current manual preform manufacturing .

Scheldebouw had the order to deliver the unique facade elements for Maison du Livre in Luxembourg.

The traditional working method

This generally results in a rather bulky preform, which can have a different infusion resistant for the resin an affect the endpart.

The new Technology

The ‘new’ technology is preforming by overbraiding, which we are doing since 1994.

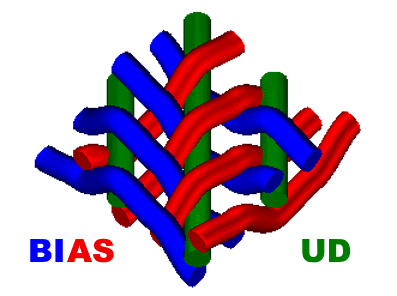

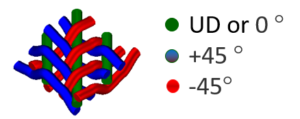

Instead of creating a wide woven fabric first, cut out sections and placing these pieces manually on the foamcore. The foam core is moved through the braiding machine. The machine below has 144 braiding carriers for the biaxial fibers ( ±45º) and a UD creel with 72 positions for the Uni Directional fibers.

During the overbraiding the fibers are placed in 3 directions within one single layer.

The bias fibers which can be ±45º oriented will take up the torsion loads in the component. The UD or 0º fibers will handle the bending loads.

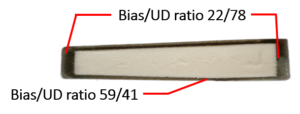

Now there is the possibility to vary the fiber amount at each of the 72 UD positions.

For the beam to handle more bending loads in one particular direction, more UD fibers in this preform region is inserted.

At the top the ratio between biaxial fibers and UD fibers is 22/78%. At the sides this is 59/41%

Several geometries were overbraided with multiple layers to get to the required thickness.

Benefits for our customer

- Receive ready to mold preforms. This saves worker time, which can do other important activities

- Cost effective preforms and low waste rates (5-10%). Overbraiding is added manuafacturing

- Reproducible due to CNC control and automated processes and therefore less surprises during infusion

- Overbraided preforms are compact, manual preforms are bulky

- Braiding angles are programmable from 30° to 70° depending on cover factor

- 0° (UD) yarns can be integrated to form a tri-axial braid (Bending and torsion)

- The ratio between Bias / UD can vary from 100/0 up to 15/85 and also vary from position to position

- Hybrids are possible in the Bias and in the UD direction

- Excellent energy absorption in crash structures. Braided structures act as crack stoppers

- Braided structures have a good resin permeability

- Concave profiles were posible and delivered

- No overlap compared to wrapping with fabrics and therefore reducing weight

Braided preform and finished facade section.

Would you like to get more information? Get in contact with one of our Agents!

Your project in 4 steps

1

The problem

2

Quotation

3

Production

Delivery

Have we convinced you yet?

Fill in the form without obligation!

Overbraiding will provide a cheap solution for your product to handle torsion and bending loads at a low waste rate.

Send us your sketch and we can go from there!