When you need controlled fiber orientation and a perfect fit around complex shapes, Eurocarbon’s tubular elastic UD is the ideal solution. This innovative sleeve combines the strength of unidirectional carbon fiber with the flexibility of an elastic weft, forming a reinforcement that conforms to your part’s geometry while maintaining structural integrity.

What Makes Tubular Elastic Carbon Fiber UD Unique?

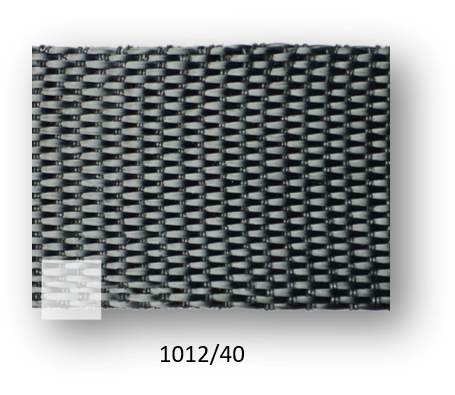

As the name suggests, the tubular elastic UD is a circular sleeve consisting of UD carbon fiber in the longitudinal direction and an elastic fiber in the weft. This configuration allows it to expand in diameter, making it exceptionally easy to apply around a preform. Once applied, the elastic weft compacts underlying layers and stabilizes the structure, which eliminates the need for adhesives or mechanical fixation.

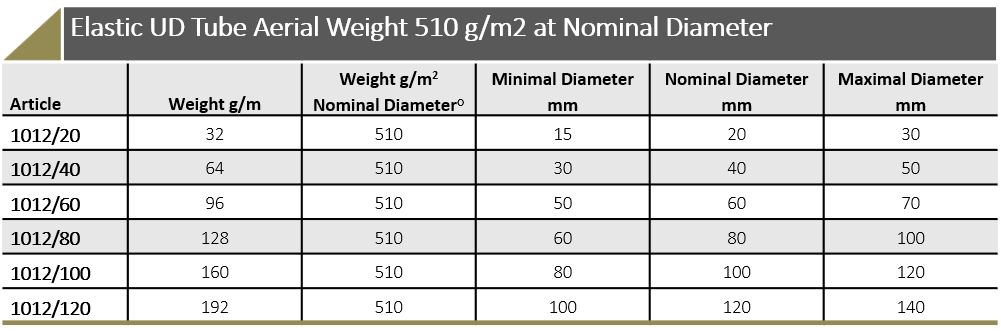

With an areal weight of 510 g/m² at nominal diameter, this reinforcement delivers high material efficiency and process reliability.

Where traditional UD woven tape may require precise cutting, manual placement and additional fixation, the tubular form allows for a cleaner and faster process—especially for cylindrical or irregular shapes.

Performance and Application Benefits

Using tubular elastic UD in your composite layup offers several key advantages:

- Layer compaction: The elastic weft applies light pressure to underlying layers

- Stable handling: Once applied, the performance remains fixed in shape

- Faster processing: Saves time compared to conventional unidirectional carbon fiber solutions

- No adhesive required: Clean and simple application

- Expandable: Adapts to different diameters without compromising alignment

- Versatile pairing: Combine with a biaxial braid for added torsional and bending stiffness

This makes it ideal for reinforcing tubular structures, joints, or any area where directional strength and form stability are required.

Photo representations of the carbon fiber elastic UD tube. The cube is 1cm.

Standard Programs

To achieve a higher level of customer service, we have successfully implemented our standard product programmes for many years.

Thermoplastics

Besides our selection of standard programs, Eurocarbon produces a large variety of tailor made constructions.

Overbraiding & equipment

Overbraiding is the technique used to produce net shape cost-effective structural preforms.

Custom made

We provide custom / tailor made solutions for our customers. Check the basic information required for a product proposal.

Would you like to get more information? Get in contact with one of our Agents!

Start Your Reinforcement Project with Confidence

Whether you are prototyping or preparing for production, the tubular elastic UD provides a reliable and efficient starting point. As part of our standard program, it is readily available and easy to integrate into your design process. If you require a custom diameter, fiber configuration or specific reinforcement property, our custom-made section is here to help. Do you need torsional strength too? Combine this unidirectional carbon fiber solution with our carbon fiber tubular braids for a complete, high-performance reinforcement package. Contact our braiding consultancy today to discuss your project—our team is ready to help you engineer stronger, smarter composite components.