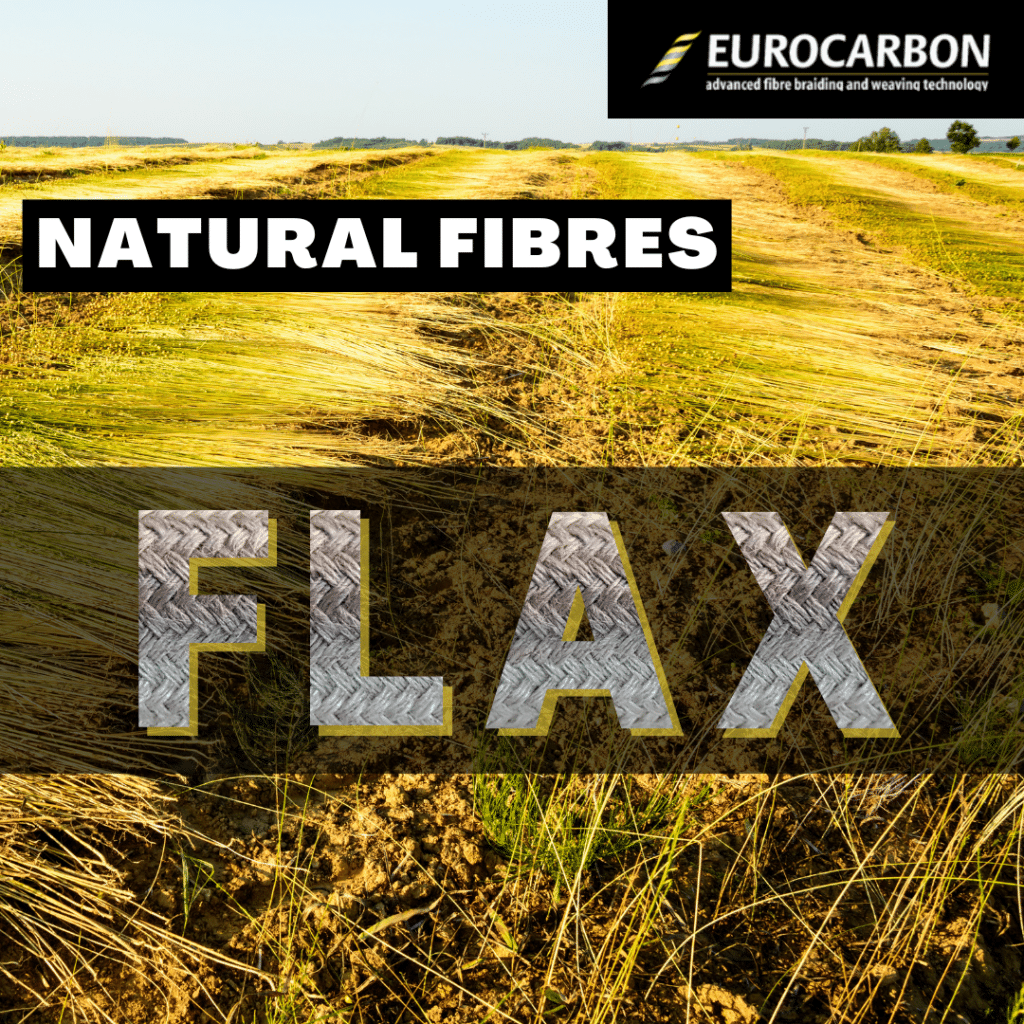

What Are Natural Fibers?

Natural fibers are fibers that are made out of natural materials that come from plants, animals, or minerals.

The raw, natural materials are spun into threads and yarns that are then braided, woven or knit into natural fabrics.

There are two general categories of natural fibers: animal-based or plant-based. Animal-based natural fibers include silk and wool, while plant-based natural fibers include cotton, linen, and jute.

Natural fibers offer several advantages when used in composites. Here are some key advantages:

- Renewable and Sustainable: Natural fibers are derived from renewable resources such as plants (e.g., jute, hemp, flax) and animals (e.g., wool, silk). Their production requires less energy compared to synthetic fibers, and they are biodegradable, making them environmentally friendly and sustainable.

- Lightweight: Natural fibers are generally lighter in weight compared to synthetic fibers, which can result in lighter and more fuel-efficient composite materials.

- Good Mechanical Properties: Natural fibers possess excellent specific mechanical properties, meaning they offer high strength and stiffness per unit weight. They have good tensile strength, can withstand high impact loads, and exhibit favorable fatigue behavior. When used in composites, natural fibers can enhance the overall mechanical performance of the material.

- Low Cost: Natural fibers are often more affordable compared to synthetic fibers. This cost advantage makes them an attractive option for various applications.

- Improved Energy Absorption: Natural fibers exhibit high energy absorption capabilities, making them suitable for applications where impact resistance is important. They can absorb and dissipate energy effectively, which enhances the safety and durability of the composites.

- Reduced Environmental Impact: Natural fibers have a lower carbon footprint compared to synthetic fibers. They require less energy during processing and release fewer greenhouse gas emissions. Additionally, they are biodegradable.

- Good Acoustic and Thermal Insulation: Natural fibers possess excellent acoustic and thermal insulation properties. When used in composites, they can improve sound dampening and thermal regulation, making them suitable for applications such as construction and automotive interiors.

- Compatibility with Polymer Matrices: Natural fibers have good compatibility with various polymer matrices, such as polypropylene and polyethylene.

It’s important to note that while natural fibers offer many advantages, they also have some limitations. For instance, they may have variations in properties due to natural variations in the raw material, and their moisture absorption characteristics can affect dimensional stability. However, with proper processing techniques and material selection, these limitations can be addressed to create high-performance natural fiber composites.

Are you interested in braids or woven tapes in natural fibers? Contact our team for more information!

Call us now: +31 (0)46 – 45 17 280

Standard Programs

To achieve a higher level of customer service, we have successfully implemented our standard product programmes for many years.

Thermoplastics

Besides our selection of standard programs, Eurocarbon produces a large variety of tailor made constructions.

Overbraiding & equipment

Overbraiding is the technique used to produce net shape cost-effective structural preforms.

Custom made

We provide custom / tailor made solutions for our customers. Check the basic information required for a product proposal.