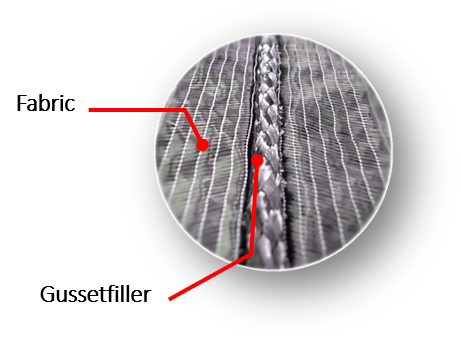

When fabrics are plied into 90-degree angles, a hollow space is created. In injection systems, this space can act as an unintended runner where resin flows ahead of the resin front. If this behavior is undesirable, a filler is required to ‘plug’ the resin channel and provide local reinforcement. The fillers are also known as ‘gusset fillers’ or ‘composite noodle filler.’

The filler area and the filler are indicated in red.

Advantages of the Gusset Filler

- Easy to form into triangular shape

- Permeability compatible with fabrics

- Provide support for stringer profiles

- Constant consistent architecture, compared to handmade fillers

- Time and money saving when it comes to blocking your undesired runners

- The fillers can be used for pultrusion rods

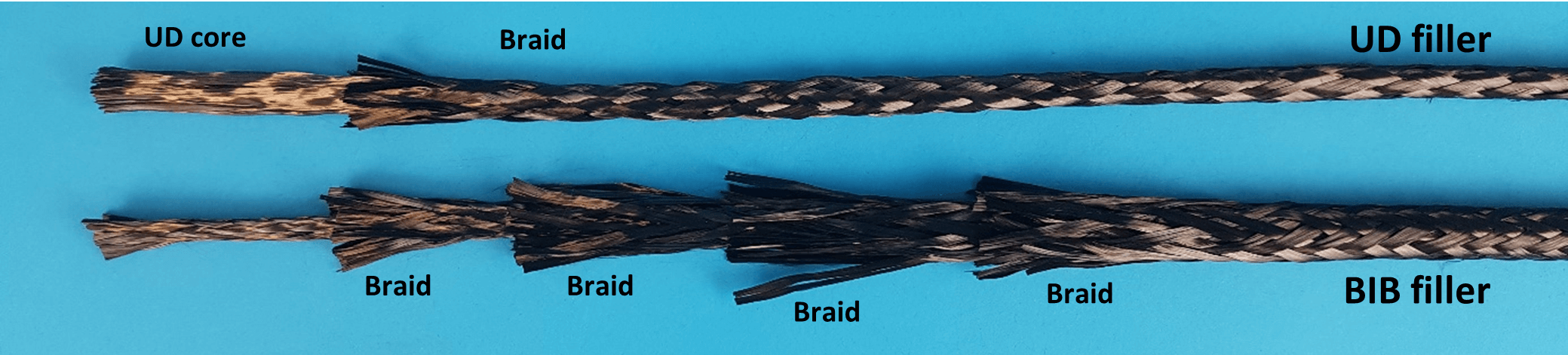

UD and Braid-in-Braid Filler: What is the Difference?

There are 2 different programs for our fillers.

- The braided UD filler ranging from 1,7mm to 10mm in diameter

- The Braid in Braid (BIB) filler 2mm to 11mm in diameter

The UD filler has a UD core inside which is easy to form into the required radius. The UD fibers will provide bending stiffness in the end product.

If the product must be ‘flexible’ or must be able to bend, then our Braid in Braid program can be used. Due to the braiding angle, which is not UD or 0 degrees oriented, the stiffness is reduced to 50% compared to the UD core type.

The standard is an effective way to start your engineering. Need something dedicated? See our custom-made section.

The standard program is also available in fiberglass

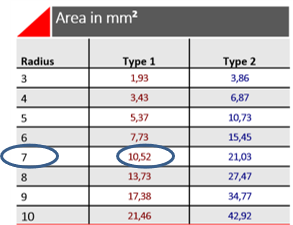

How to Select the Correct Filler Size

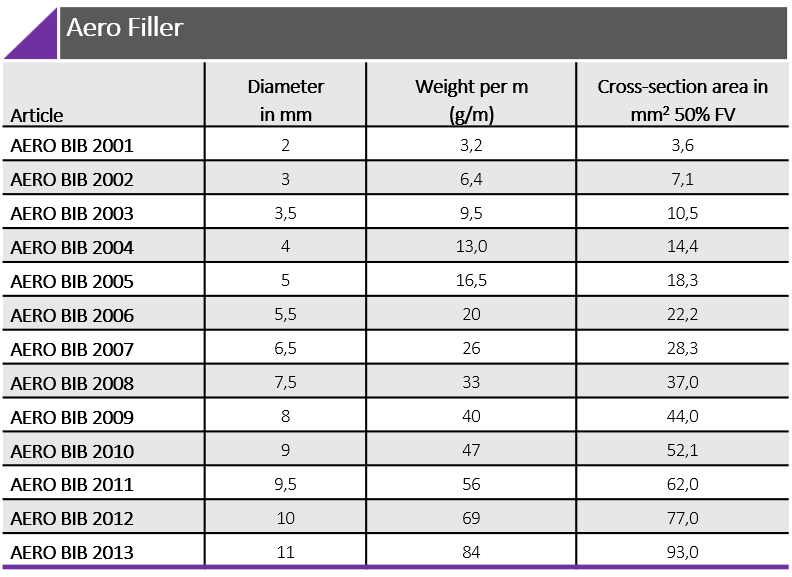

If the type of filler is chosen, depending on your product performance, the correct filler dimension must be chosen. Each filler has a specific surface area in mm2 at a fiber volume fraction of 50%.

Follow the following steps to define a suitable filler for your application.

Determine the radius type for the filler, 1 or 2.

For example, R= 7 type 1 BIB filler

Find your radius for the filler in the table and read the surface area in mm2 associated with type 1 or 2.

Result is 10,52 mm2

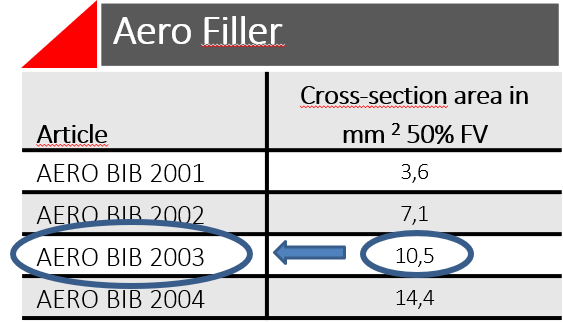

Look at the table for the cross section in mm2 for the filler.

Find a close match between the calculated mm2 and the mm2 from the filler program.

The best match is Aero BIB 2003

Calculated = 10.52mm2, match is 10.5mm2

Our Standard Aero Filler Program: Braid-In-Braid (BIB)

The program with NO UD inside. Aerospace certified carbon fibers.

Our Standard Program: UD Filler

The program with UD inside. Aerospace grade carbon fiber on request.

Standard Programs

To achieve a higher level of customer service, we have successfully implemented our standard product programmes for many years.

Thermoplastics

Besides our selection of standard programs, Eurocarbon produces a large variety of tailor made constructions.

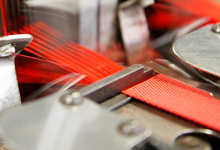

Overbraiding & equipment

Overbraiding is the technique used to produce net shape cost-effective structural preforms.

Custom made

We provide custom / tailor made solutions for our customers. Check the basic information required for a product proposal.

Would you like to get more information? Get in contact with one of our Agents!

Select the Right Filler for Reliable Reinforcement

Whether you require enhanced resin flow control, local reinforcement, or a lightweight perform element, our gusset fillers—including both UD and Braid-in-Braid options—offer a reliable and efficient solution. With their consistent construction and compatibility with composite processes, filler radius-style geometries such as triangular inserts become easier to manage and standardize. Explore our standard programs or contact us for custom-made filler configurations tailored to your application—as a specialist in braiding consultancy we are ready to support your next composite design challenge.