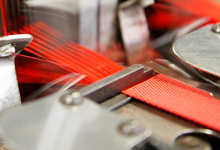

If you are looking for a lightweight yet high-strength filler or reinforcement material, chopped carbon fiber strands offer an excellent solution. These short carbon fibers are widely used in compression and injection molding, where they improve part performance, durability, and even electrical properties. From industrial machine parts to consumer products, chopped carbon fiber delivers targeted strength—without compromising formability or efficiency.

For What Is Chopped Carbon Fiber Used?

Chopped carbon fiber strands are commonly used in compression and injection molding processes to create high-performance parts. These parts—often referred to as forged carbon fiber composites—are ideal for demanding applications in sectors such as:

- Automotive (gears, covers, brackets)

- Bicycle and sporting equipment

- Industrial machinery parts

- Consumer electronics and appliance housing

Due to their short, free-flowing form, chopped fibers easily conform to intricate geometries and detailed features during molding. Additionally, they are suitable for DMC (Dough Molding Compound) and BMC (Bulk Molding Compound) formulations, either as a main reinforcement or as an additive to enhance strength and stiffness.

For customers seeking hybrid properties, a carbon and fiberglass mix (70/30) is also available—balancing stiffness and cost-efficiency.

Key Properties and Performance Advantages

The properties of chopped carbon fiber make them ideal for a variety of structural and functional roles:

• Excellent corrosion resistance

• Creep and fatigue resistance

• Rigid and durable

• High formability

• Anti-static behavior

• Gap filler

• Multi-resin compatibility

• Aesthetic surface quality

Even in small volumes, chopped fibers significantly enhance part performance—boosting strength, conductivity, and structural reliability.

| Fiber Properties | Units | Values |

| Density | g/cm³ | 1,77 – 1,8 |

| Fiber length copped | mm | 6 – 9 – 12 – 18 – 24 |

| Filament diameter | μm | 7 |

| Tensile strength | Mpa | 4100 – 4900 |

| Tensile modulus | Gpa | 230- 240 |

| Elongation at break | % | 1,5 – 2 |

| Sizing type | Epoxy | |

| Sizing level | Weight % | 1-1.3 |

Standard chop size is 6 mm. Other sizes available on request.

Standard Programs

To achieve a higher level of customer service, we have successfully implemented our standard product programmes for many years.

Thermoplastics

Besides our selection of standard programs, Eurocarbon produces a large variety of tailor made constructions.

Overbraiding & equipment

Overbraiding is the technique used to produce net shape cost-effective structural preforms.

Custom made

We provide custom / tailor made solutions for our customers. Check the basic information required for a product proposal.

Would you like to get more information? Get in contact with one of our Agents!

Get Started With Chopped Fiber Today

Whether you are developing high-performance molded parts or looking to reinforce your composite mix, chopped carbon fiber offers the strength, efficiency, and versatility you need. At Eurocarbon, we supply chopped carbon fiber in a range of formats to match your processing and performance requirements—including hybrid mixes on request. Contact our braiding consultancy today to explore how chopped fibers can improve your product design, durability, and manufacturability.