The Advantages of Overbraiding

When producing a composite preform by hand, several steps are required before layup can begin. First, a braid or another type of reinforcement needs to be purchased—or produced—separately. This material must then be manually cut, shaped, and positioned on the mandrel. Each of these actions introduces handling losses, material waste, and considerable operator time. Manual preforming is therefore labour-intensive and prone to variation.

Overbraiding eliminates these inefficiencies entirely.

In overbraiding, the reinforcement is produced directly onto the mandrel in a single automated process. The machine simultaneously creates the textile and applies it to the product, with minimal waste during lead-in and lead-out. No intermediate braid needs to be manufactured, and no manual layup is required.

Beyond these practical advantages, overbraiding also enables unique reinforcement architectures that cannot be created by hand.

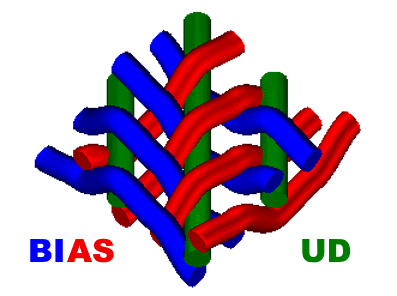

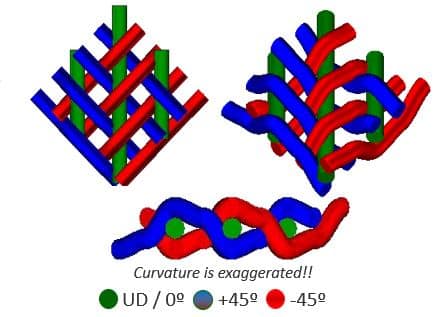

Only through overbraiding is it possible to produce a triaxial braid—a combination of axial and ± bias yarns—in one integrated layer, even on products with changing diameters. This structure provides bending stiffness and torsional strength in a single pass, something no manual layup or off-the-shelf braid can achieve without multiple layers and substantial labour.

In short, overbraiding offers:

- One integrated process instead of multiple manual steps

- Minimal material waste at start and end of production

- Significantly reduced operator time

- High repeatability through computer-controlled parameters

- Consistent quality for small or large series

- The ability to create triaxial braids over variable geometries

- Bending and torsional reinforcement in one homogeneous layer

Overbraiding delivers a faster, cleaner, and more capable method of producing high-performance composite preforms—especially where uniformity, structural performance, and production efficiency are essential.

What are triaxial braids?

Triaxial braids are reinforcement structures made from three yarn orientations: axial fibres running along the length of the part, combined with ±-angle bias fibres braided around them. This creates a single, consolidated layer that provides both bending stiffness (axial fibres) and torsional strength (± fibres). Triaxial braids are especially effective on components with varying diameters, where they offer uniform mechanical performance and excellent drapability.

Would you like to get more information? Get in contact with one of our Agents!

Your project in 4 steps

1

The problem

2

Quotation

3

Production

Delivery

Have we convinced you yet?

Fill in the form without obligation!

Overbraiding will provide a cheap solution for your product to handle torsion and bending loads at a low waste rate.

Send us your sketch and we can go from there!