In addition to our selection of standard programs, Eurocarbon specializes in producing a wide range of custom braids and custom-made tape tailored to your specific application requirements. These custom reinforcements offer a significant advantage: they can be precisely engineered to match the performance demands of your component. This leads to optimized functionality and can reduce material costs or enhance mechanical properties compared to standard solutions.

Thanks to our experience, we can engineer custom braids and custom-made tape constructions to meet the demands of high-performance composite applications across various industries.

To create a custom braid or woven tape, we require a minimum set of technical specifications, as outlined in the sections below. In the next sections the required information is described.

Minimum Required Information for Custom Braids

To design a new custom braid, we require the following specifications:

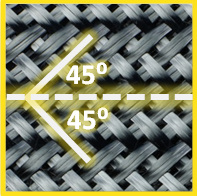

- Diameter measured at a 45-degree braiding angle (or at a specific angle).

- Fiber materials: e.g. carbon, e-glass, aramid, etc.

- Hybrid construction? We can braid combinations such as carbon and glass. The standard ratio is 50/50, but alternative ratios are possible.

- Weight of the braid at a 45-degree angle, or areal weight at 45 degrees.

If you have an existing braid sample for evaluation, please provide a piece approximately 20 cm in length.

Minimum Required Information for Custom-Made Woven Tapes

To define a custom-made tape, the following information is needed:

- Tape width

- Weight per m²

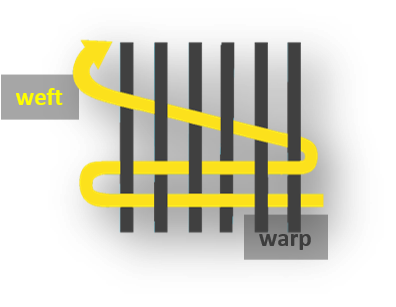

- Fiber type in warp (e.g., fiberglass, aramid, carbon)

- Fiber type in weft: (e.g., fiberglass, aramid, carbon)

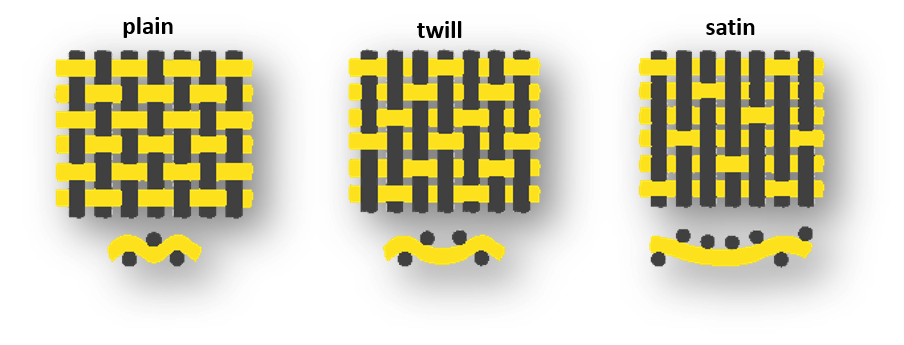

- Weave style (plain, twill, satin, or other – see options below)

- Threads per cm in warp (if available)

- Threads per cm in weft (if available)

If the thread density is unknown, we require the warp/weft ratio by weight. Please also provide a 20 cm sample for assessment if available.

Standard Programs

To achieve a higher level of customer service, we have successfully implemented our standard product programmes for many years.

Thermoplastics

Besides our selection of standard programs, Eurocarbon produces a large variety of tailor made constructions.

Overbraiding & equipment

Overbraiding is the technique used to produce net shape cost-effective structural preforms.

Custom made

We provide custom / tailor made solutions for our customers. Check the basic information required for a product proposal.

Would you like to get more information? Get in contact with one of our Agents!

Partner with Us for Custom Solutions

Whether you are developing a new application or improving an existing design, our braiding consultancy is ready to support you with expertly engineered custom braids and custom-made tape. Our technical team will collaborate closely with you to translate your specifications into high-quality, performance-driven reinforcements. Reach out to us today to discuss your requirements—we are here to deliver the right solution for your composite challenge.