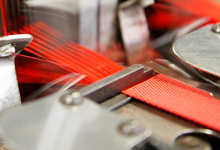

Eurocarbon offers a comprehensive program of high-quality carbon fiber braids and sleeves designed for structural reinforcement in advanced composite applications. Whether you require torsional resistance, seamless surface coverage, or enhanced mechanical strength, our range of braided carbon fiber sleeves provides reliable, off-the-shelf solutions tailored to a wide range of industry needs. From lightweight to heavy-duty applications, our carbon braided sleeves are engineered for efficient, low-waste, and high-performance manufacturing.

Why Use Carbon Fiber Braids?

Using a carbon fiber braid provides several functional and manufacturing advantages. These tubular braids are seamless and conform easily to the surface of your part, making them ideal for applications that demand uniform coverage and high torsional load resistance. Their net-shape adaptability drastically reduces material waste, cutting costs and streamlining your production process.

- Braided carbon fiber structures help absorb torsional forces and improve damage tolerance

• Their tubular shape eliminates seams and simplifies application

• Carbon fiber sleeves can be easily cut to length, reducing waste to a minimum

• The braid architecture provides uniform fiber distribution and excellent impact resistance

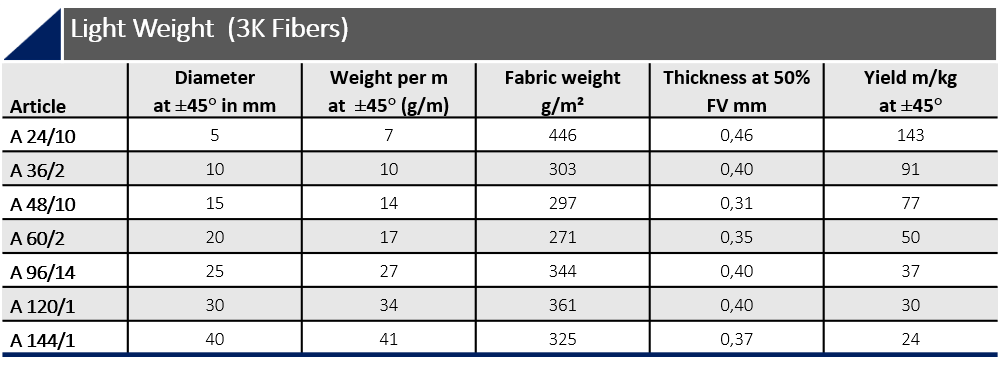

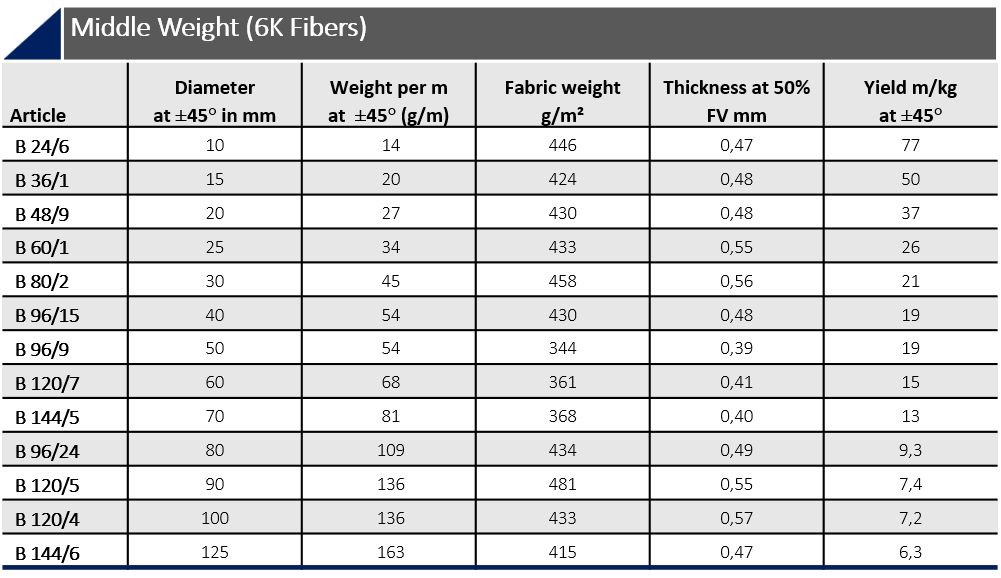

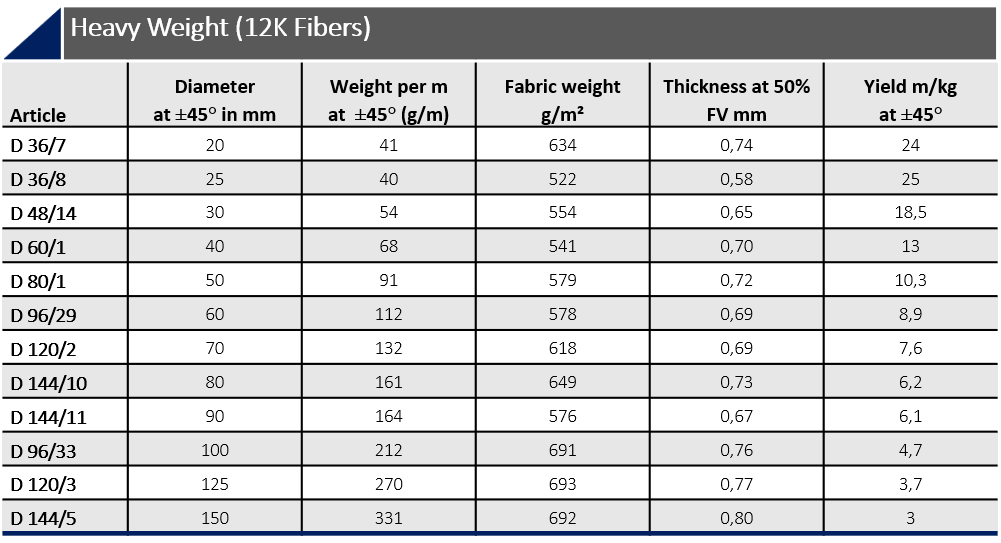

Our program includes carbon braided sleeves made from 3K, 6K and 12K fibers, resulting in light (340 g/m²), medium (420 g/m²), and heavy (600 g/m²) braid options. These serve as a solid starting point for engineering teams exploring composite part reinforcement. For projects requiring additional stiffness or multidirectional reinforcement, these sleeves can be combined with our Carbon tubular elastic UD for enhanced bending performance.

Flexible Options and Customization

While our standard braided carbon fiber sleeves cover a wide range of applications, we understand that specific projects demand tailored solutions. That’s why we also offer fully customizable to meet your exact design and performance criteria. Whether you need a specific fiber orientation, wall thickness or hybrid material solution, our team is ready to advise and develop the right sleeve or braid for your component.

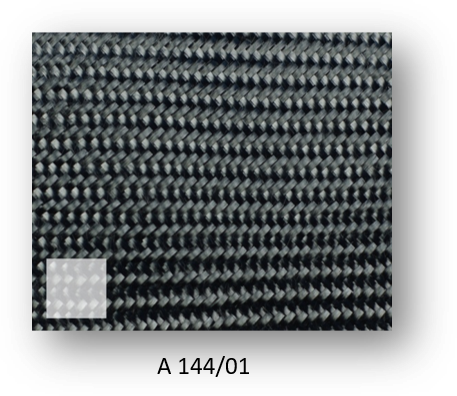

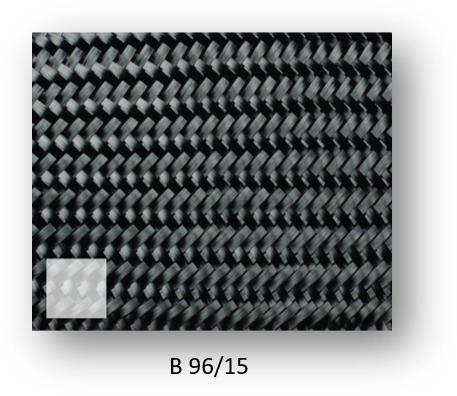

Photo representations of our braids. The cube is 1cm.

Standard Programs

To achieve a higher level of customer service, we have successfully implemented our standard product programmes for many years.

Thermoplastics

Besides our selection of standard programs, Eurocarbon produces a large variety of tailor made constructions.

Overbraiding & equipment

Overbraiding is the technique used to produce net shape cost-effective structural preforms.

Custom made

We provide custom / tailor made solutions for our customers. Check the basic information required for a product proposal.

Would you like to get more information? Get in contact with one of our Agents!

Get in Touch for the Perfect Fit

Whether you are prototyping or scaling up production, Eurocarbon’s braided carbon fiber sleeves deliver the strength, adaptability, and quality you need. All items in our standard program are in stock and ready to ship. In addition to sleeves, we also offer complementary solutions such as chopped carbon fiber, ideal for molding applications and gap filling. Let us help you strengthen your next composite product with precision-engineered carbon fiber reinforcements and reach out to our braiding consultancy today.