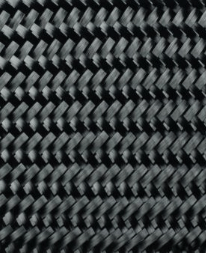

What Is Biaxial Carbon Fiber?

Biaxial carbon fiber is a type of reinforcement fabric constructed with carbon fibers oriented in two directions, typically +45° and -45°, or 0° and 90°. The fibers are stitched together without crimping, preserving their mechanical properties and ensuring even load distribution across the composite part. This bidirectional architecture offers superior in-plane strength, ideal for components subject to multidirectional stress. Besides stitched fabrics, biaxial braid is another form of biaxial reinforcement. This braid is particularly suitable for components like tubes, joints, and other curved profiles where both torsional and bending stiffness are critical.

The Advantages of Biaxial Carbon Fiber

- Excellent multidirectional strength: Due to fiber orientation in two axes

- Lightweight: With high strength-to-weight ratio

- Flexible and drapeable: Conforms well into complex shapes

- Consistent quality: Due to stable stitching and controlled fiber alignment

- Compatible with various resins: Including epoxy, vinylester and polyester

- Low waste: Especially when cut to net shape or used in perform assemblies

This optimal balance of stiffness and conformability makes biaxial carbon fiber a go-to solution for advanced composite designs.

Standard and custom-made

In-house production

ISO 9001 certified quality management

What our customers say about us

Applications Across Industries

Biaxial carbon fiber is widely used in sectors such as:

- Aerospace

- Automotive

- Marine

- Sports equipment

- Construction

Its versatility and mechanical reliability make it a trusted solution for both prototyping and full-scale production.

Standard Dimensions and Custom Options

At our braiding consultancy, our biaxial carbon fiber reinforcements are available in a variety of standard areal weights and widths. Common configurations include:

- ±45° and 0°/90° orientations

- Areal weights typically ranging from 200 g/m² to 600 g/m²

- Widths tailored to suit your molding or layup process

For projects with unique requirements, we also offer custom-made fabrics, where we adjust the fiber angles, weights and widths based on your specifications. Our engineering team is available to assist with product development and prototyping if needed.

Get in touch with our braiding experts

Discover Your Fiber Solution Today

Whether you are looking to enhance performance, reduce weight or optimize your layup process, biaxial fiber offers a proven, flexible, and reliable reinforcement option. We are here to support your project from design to production with both off-the-shelf and custom-engineered solutions. Get in touch with our team today to discuss the best biaxial carbon fiber configuration for your application.