Eurocarbon is founded in 1982 with the speciality to braid and weave with the ‘new’ material: carbon fibre. Hence the name Eurocarbon.

Since then we have developed a plurality of products. Many of them are now in our standard programs, delivered off the shelf.

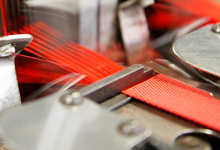

To produce these products, Eurocarbon has a large selection of braiding and weaving machines to choose from.

braiding and weaving machines to choose from.

Besides the specialisation in continuous production of braids and woven tapes, we have specialized ourselves in the overbraiding technique since 1994 as a pioneer.

The overbraiding technique is used to braid reinforcement fibres directly onto a mandrell, creating a preform. The benefit of this proces is an automated, cheap and repeatable process, which creates preforms ready for injection with RTM or an other infusion process.

One of our overbraiding successes is the Crashcone for the Mercedes McLaren SLR.

We decided to engineer and build (over)braiding installations and help equipment for any process to keep our know-how inside and to be very reactive to customer demands. This capability is also used to make normal tailor made products where high(er) degree of engineering is required.

If the chemistry is right, we sell turn key overbraiding solutions for our customers. The biggest example is the 288/192 carrier overbraider delivered turn-key to National Compostes Centre NCC in Bristol.

We are working closely with universities, research institutes and composite producers to keep up with the latest trends.

Quality is a very important factor for Eurocarbon.

Therefore we have implemented the ISO 9001 system a long time ago.

Download the certificates by clicking this link.

Please see the following for more information about Eurocarbon and its capabilities:

Standard Programs

To achieve a higher level of customer service, we have successfully implemented our standard product programmes for many years.

Thermoplastics

Besides our selection of standard programs, Eurocarbon produces a large variety of tailor made constructions.

Overbraiding & equipment

Overbraiding is the technique used to produce net shape cost-effective structural preforms.

Would you like to get more information? Get in contact with one of our Agents!

Your project in 4 steps

1

The problem

2

Quotation

3

Production

Delivery

Have we convinced you yet?

Fill in the form without obligation!

Our sales team will invetigate your request and propose the best solution for your application.

Even when a bit information is shared we know how to proceed further. Ofcourse if a NDA is required, we can settle this together.